Material: TP 304/304L, 316/316L, 201, 202, 310S, 321, 800, 600, etc.

Tube delivery condition: bright annealing (BA)

Tube type: weld, TAW

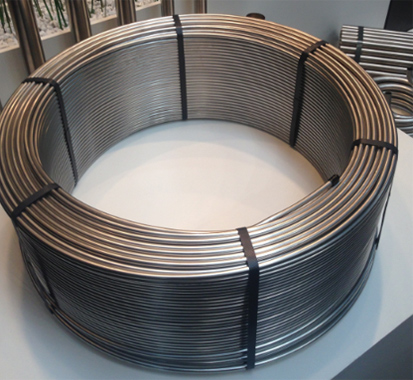

Coil Lengths: max 3000 m per coil tube

Standard: ASTM A269, A249

O.D. from 3 to 25.4mm

W.T. from 0.3 to 2.0mm

Chemical composition:

in accordance with ASTM A269

Mechanical and technical properties:

in accordance to ASTM A269

Soft annealed max. Hardness 150 HV10 Tolerance +10 points

Model type and surface integrity:

in accordance with ASTM A269

Surface roughness Ra < 0.5 μm

Cleanliness of the tubes:

bore cleanliness in accordance to DIN 8905. The coils shall be dry, clean and free from swarf, drawn and roller marks.

Pressure Test:

100% tested at the appropriate pressure stated under water.

All coils must be flushed and dried after pressure testing to avoid contamination.

Tolerance:

D4/T4, Diameter of ball for ball bearing check

PMI TEST 100% GOOD

ELONGATION IN 50MM LONGITUDINAL

HEAT TREATMENT 1050℃ FOR 5MIN (W.Q.)

MEASUREMENTS & SURFACE: GOOD

IC ASTM A-262 PRACTICE E.NACE MR0175-MR0103

FLARING TESTING AS ASS. TO ASTM A1016

FLATTENING TESTING IS ACC. TO ASTM A1016

100% HYDROSTATIC TEST AS PER A1016/A1016M

MARKING SAMPLE: JW STEEL, TP316/316L, welded, Bright Annealed, ASTM A269, OD3/8'' X WT0.035'' HEAT NO.160326T22

MATERIAL ACC TO ASME SECTION II PART A 2010 EDIT

CERT TO EN 10204 3.1 IN ACCORDANCE WITH PED ANNEX 1.PARAGRAPH 4.3

Package:

A non adhesive label shall be affixed to each coil in accordance to DIN EN

ASTM A269 In addition each packing unit is to be labeled with the coil length (front size 20mm).

The ends of the coil shall be sealed with end-caps, each coil has to be tied three times (no adhesive tape).